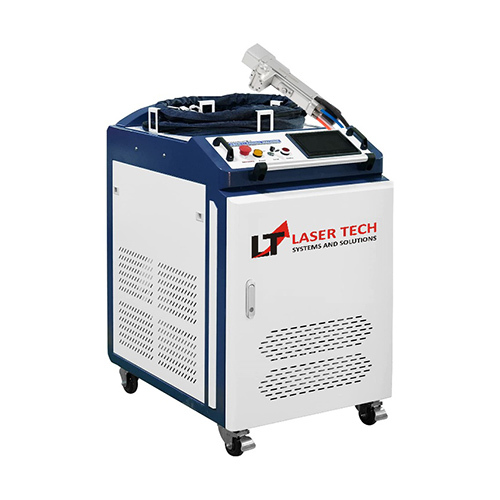

CW लेजर क्लीनिंग मशीन

651000 आईएनआर/Unit

उत्पाद विवरण:

- उपयोग व्यावसायिक

- मटेरियल मेटल

- टाइप करें सफाई उपकरण के पुर्जे

- शर्त

- साइज अनुकूलित

- फ्यूल टाइप इलेक्ट्रिक

- प्रॉडक्ट टाइप 2kw सीडब्ल्यू लेजर सफाई मशीन

- अधिक देखने के लिए क्लिक करें

X

CW लेजर क्लीनिंग मशीन मूल्य और मात्रा

- यूनिट/यूनिट

- 1

- यूनिट/यूनिट

CW लेजर क्लीनिंग मशीन उत्पाद की विशेषताएं

- सफेद, नीला

- 2kw सीडब्ल्यू लेजर सफाई मशीन

- 150KG

- व्यावसायिक

- अनुकूलित

- सफाई उपकरण के पुर्जे

- मेटल

- इलेक्ट्रिक

CW लेजर क्लीनिंग मशीन व्यापार सूचना

- ROHINI SEC.7

- कैश इन एडवांस (CID)

- 50 प्रति महीने

- 10 दिन

- Yes

- ऑल इंडिया

उत्पाद वर्णन

Laser Rust Cleaning Machine Fast, Safe & Eco-Friendly Experience next-level cleaning with our Laser Rust Cleaning Machine, built for fast and precise removal of rust, paint, oil, and oxides from metal surfaces. No chemicals, no abrasivesjust clean surfaces with zero damage. Key Features: - Non-contact laser cleaning: No damage to base material - Eco-friendly: No chemicals, dust, or secondary pollution - Portable & ergonomic: Handheld design for on-site jobs - Adjustable power settings: For different materials and cleaning needs - Low maintenance: Long-lasting fiber laser source with stable output Applications: - Rust removal from industrial equipment and tools - Paint and oxide layer removal from metal surfaces - Cleaning before welding or coating - Mold and die cleaning in manufacturing - Restoration of old metal parts and structures Clean smarter, not harder. संपर्क करें now for pricing, demo, or और जानकारी!Advanced Laser Cleaning Technology

Utilizing burn-off/thermal system technology, the Rust Laser Cleaning Machine offers a non-contact method to efficiently remove rust and surface contaminants. Its electric operation eliminates the need for harsh chemicals or manual scraping, significantly reducing labor and environmental hazards while delivering highly precise results.

Custom Solutions for Commercial Use

With fully customizable sizes and robust metal construction, this laser cleaning machine is ideal for commercial businesses requiring flexibility and adaptability. Whether tackling large machinery or intricate parts, the equipment is engineered for durability and consistent performance, ensuring your workspace remains both productive and safe.

Reliable Support from Indian Suppliers

Supported by experienced distributors, manufacturers, and service providers in India, the Rust Laser Cleaning Machine comes with comprehensive after-sales service and spare parts availability. This network ensures you always have local expertise and prompt support to minimize downtime and keep operations running smoothly.

FAQs of Rust Laser Cleaning Machine:

Q: How does the Rust Laser Cleaning Machine remove rust from metal surfaces?

A: The machine utilizes a burn-off or thermal system, where a concentrated laser beam is directed at the rusted surface. The thermal energy instantly vaporizes or burns off the rust, leaving the metal beneath unharmed and clean without any need for abrasive methods or chemicals.Q: What are the key benefits of using this laser cleaning equipment for commercial purposes?

A: This equipment offers significant advantages such as reduced labor, elimination of chemical cleaning agents, precise and uniform rust removal, minimal damage to base materials, and enhanced safety. Its efficient operation leads to lower maintenance costs and improved productivity for commercial users.Q: When is it advisable to use a laser cleaning machine instead of traditional rust removal methods?

A: Laser cleaning is ideal when precision and efficiency are required, especially on delicate, complex, or large metal surfaces where traditional abrasive or chemical methods may be ineffective, slow, or damaging. It is particularly beneficial for frequent cleaning tasks in commercial environments.Q: Where can I purchase or service the Rust Laser Cleaning Machine in India?

A: This machine is available through multiple channels including authorized distributors, manufacturers, service providers, and suppliers across India. Reliable after-sales service and support are also offered to ensure continued performance and longevity of your machine.Q: What is the process for operating the Rust Laser Cleaning Machine?

A: Operation involves positioning the machine near the target surface, configuring the laser settings according to the rust thickness and material type, and methodically scanning the laser over the affected area. Always follow the provided safety instructions and wear appropriate protective equipment during use.Q: How can I customize the size of the machine to fit my workspace requirements?

A: You can specify your required machine dimensions during the ordering process. The manufacturer will design and fabricate the system to suit your unique workspace or operational needs, ensuring optimal integration into your commercial setting.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email